1. The gearbox of

the main gearbox (Jie brand reducer) is equipped with a cold oil circulation

spray device, so that the gearbox bearings and gears are fully lubricated and

their service life is greatly extended;

2. The main

gearbox is independently researched, designed and produced according to the

operating characteristics of the oil press. It has the characteristics of large

gear module, high strength, torsion resistance, thrust resistance and low

operating noise. The gears adopt hard tooth surface grinding technology;

3. The snails and

bars are made of cemented carbide and have a service life of not less than 6

months;

4. The outer

cover plate of the oil press is made of 304 stainless steel;

5. The oil press

pulley is a Martin wheel;

6. The surface of

the oil press has been shot blasted to remove rust, polished and then painted

twice with Everest brand glossy anti-rust paint. The topcoat is Goldfish brand

phthalocyanine green topcoat;

7. The main shaft

and the reducer are connected by a square-head coupling. This connection method

does not break the shaft and effectively prevents the main shaft from fatigue

fracture. The main shaft is a hollow cooling shaft and is equipped with an electric

cake adjusting device;

Instruction:

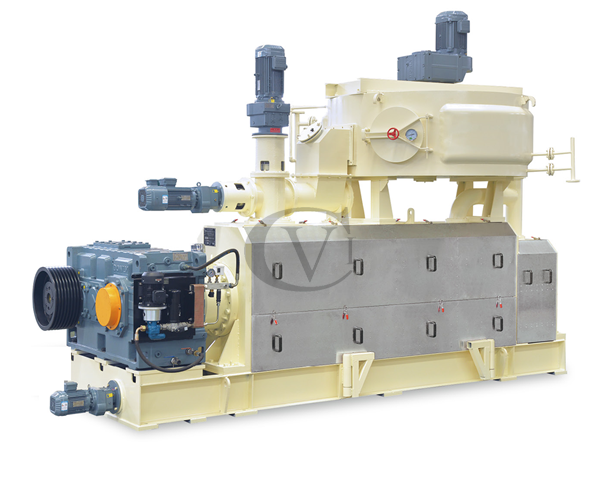

The DZY319B pretreatment oil press machine is an upgraded product of the original 32-type oil press. Compared with the

original model, it has a hollow shaft water-cooling device to avoid cake

sticking. The feeding mode is changed to reverse feeding. The gearbox is an

up-and-down opening and closing box, and the gear It adopts the gear grinding

process and is equipped with a cold oil circulation system, which has a longer

service life and easier maintenance. The pressed cake has good shaping effect

and good color, which is conducive to leaching.

This pretreatment oil press machine has a wide range of adaptability, and the requirements for moisture and

temperature are not too strict. It is also a high and low temperature

dual-purpose machine. Even if the material temperature is pressed at a low

temperature of 70-80 degrees, it will not affect the residual oil index of the

dry cake and can ensure Low denaturation of protein in cake.

The combined oil press machine with steam cooker occupies a

small area, reduces maintenance costs and is easy to manage.

Main equipment feature:

1. The gearbox of

the main gearbox (Jie brand reducer) is equipped with a cold oil circulation

spray device, so that the gearbox bearings and gears are fully lubricated and

their service life is greatly extended;

2. The main

gearbox is independently researched, designed and produced according to the

operating characteristics of the oil press. It has the characteristics of large

gear module, high strength, torsion resistance, thrust resistance and low

operating noise. The gears adopt hard tooth surface grinding technology;

3. The snails and

bars are made of cemented carbide and have a service life of not less than 6

months;

4. The outer

cover plate of the oil press is made of 304 stainless steel;

5. The oil press

pulley is a Martin wheel;

6. The surface of

the oil press has been shot blasted to remove rust, polished and then painted

twice with Everest brand glossy anti-rust paint. The topcoat is Goldfish brand

phthalocyanine green topcoat;

7. The main shaft

and the reducer are connected by a square-head coupling. This connection method

does not break the shaft and effectively prevents the main shaft from fatigue

fracture. The main shaft is a hollow cooling shaft and is equipped with an electric

cake adjusting device;

Main data:

|

Model |

DZY-319B pretreatment oil press machine |

DZY-319 screw oil press machine |

|

Processing capacity |

160ton/day (rape seeds) |

80-100Ton/day(rape seeds) |

|

Power |

Main motor 110kw, mixing reducer 11kw, Feeding reducer 2.2kw, cake motor 1.1kw |

|

|

Cooker |

2 layers, 1800mm dia, carbon steel |

|

|

Oil residue in cake |

≤18% |

≤8% |

|

Installation size |

4490x2375x4285mm |

4490x2375x4285mm |

|

Weight |

13Ton |

13Ton |