1. The press screw alloy material has a service life of more than 1 year, the surface of the press bar is plated with alloy chromium, and the internal carburizing treatment has a service life of 6 months.

2. The hood guard plate is made of stainless steel 304 guard plate, the connection between the coupling and the reduction box is added with a stainless-steel guard plate, the thickness is 1.2mm, the feeding port sealing material is stainless steel seal 1.2mm,

The sealing material of the top cover connecting the gearbox and the large shaft is stainless steel with a thickness of 1.2mm. The connection between the frying pan and the oil press body is tightly sealed. The top cover of the discharge port and the top cover of the pressing chamber are made of 304 stainless steel with a thickness of 4mm.

The feeder is carburized and quenched to a thickness of 8mm.

3. The V-belt pulleys of the reducer and motor are Martin pulleys, and the main shaft is equipped with a cooling system and a rotating joint made of metal stainless steel.

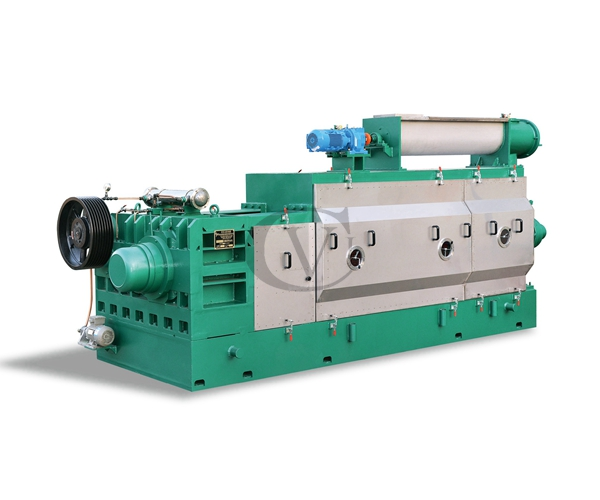

Instruction:

The large screw oil press machine can press sunflower

seeds, corn germ, peanut, cotton seeds, rape seeds and etc. The pressed cake has good

shaping effect and good color, which is conducive to leaching. This

equipment has a wide range of adaptability, and the requirements for moisture

and temperature are not too strict. It is also a high and low temperature

dual-purpose machine. Even if the material temperature is pressed under low

temperature conditions of 80-90 degrees, it will not affect the residual oil

index of the dry cake and can ensure low denaturation of protein in cake.

Main feature:

1. The press

screw alloy material has a service life of more than 1 year, the surface of the

press bar is plated with alloy chromium, and the internal carburizing treatment

has a service life of 6 months.

2. The hood guard

plate is made of stainless steel 304 guard plate, the connection between the

coupling and the reduction box is added with a stainless-steel guard plate, the

thickness is 1.2mm, the feeding port sealing material is stainless steel seal

1.2mm,

The sealing

material of the top cover connecting the gearbox and the large shaft is

stainless steel with a thickness of 1.2mm. The connection between the frying

pan and the oil press body is tightly sealed. The top cover of the discharge

port and the top cover of the pressing chamber are made of 304 stainless steel

with a thickness of 4mm.

The feeder is

carburized and quenched to a thickness of 8mm.

3. The V-belt

pulleys of the reducer and motor are Martin pulleys, and the main shaft is

equipped with a cooling system and a rotating joint made of metal stainless

steel.

Main data:

|

Model |

DZY-338B Large oil press |

|

Processing capacity |

160-180ton/day (rape seeds) |

|

Power |

Main motor 200kw, force feeder 5.5kw, cake reducer 0.55kw, oil pump

0.75kw, frequency feeder 3kw |

|

Materials |

All bears are brand bearings, main shaft 40Cr with tempering |

|

Oil residue in cake |

13-15% |

|

Installation size |

5600x2950x3225mm |

|

Weight |

16000kgs |